The Art of the Strike

By: Chris AdamsChar cloth is designed to catch a spark easily due to its low ignition temperature, making it an ideal tinder for lighting fires. The process begins with small squares of 100% cotton or linen. These fabric squares are placed in an almost airtight container, such as a metal tin with a small vent hole. The container is then slowly heated over a long period, a process known as pyrolysis, which involves the thermal decomposition of materials at elevated temperatures in an inert atmosphere. This process transforms the fabric, leaving behind carbon pieces that can catch and hold a spark. Once ignited by a spark from flint and steel, the char cloth is placed in a bird’s nest of natural fiber. Blowing gently on the glowing charcloth ignites the bird’s nest into flames.

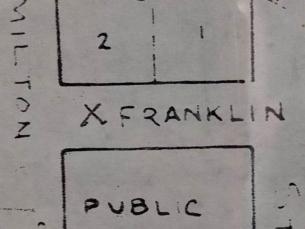

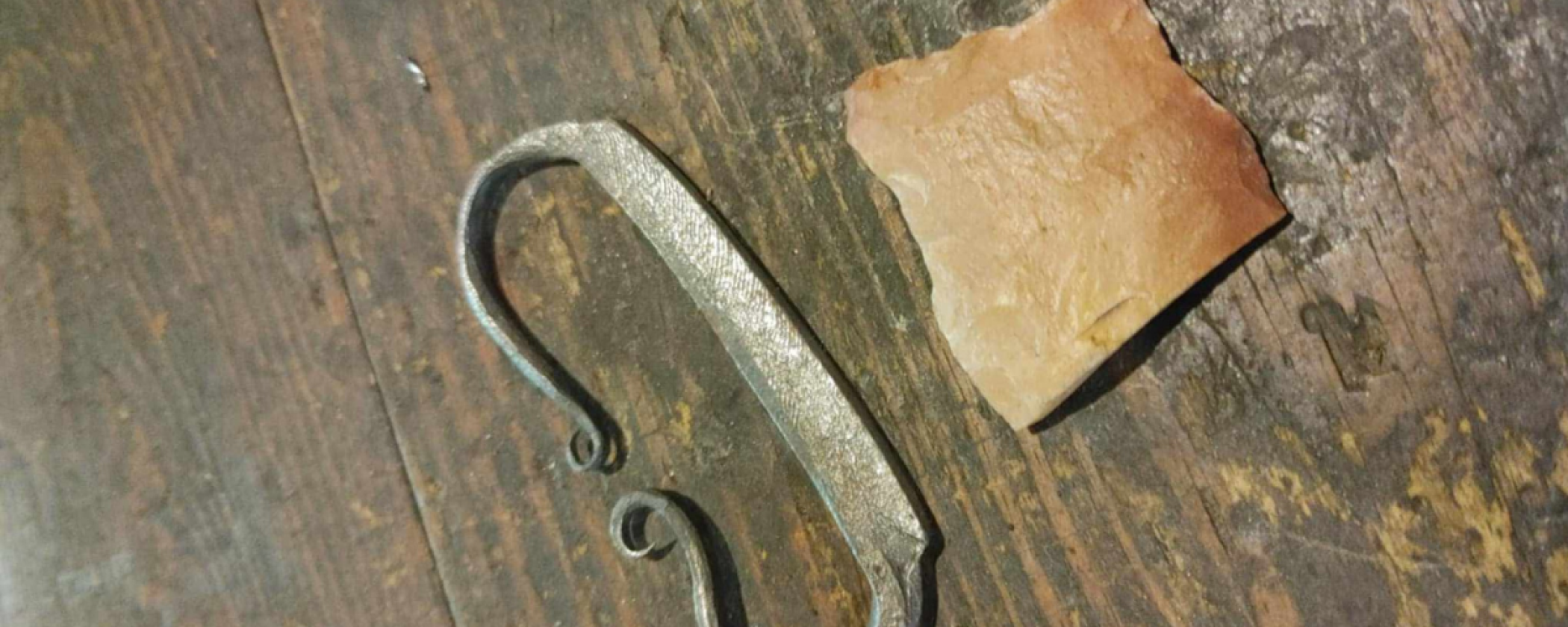

Flint is a generic term for the stone used with steel to create sparks. In our region, our blacksmith uses novaculite, a native stone found along most rivers and creeks in Arkansas. Selecting the right steel is crucial, as a striker will only spark if the steel has a fair amount of carbon. While options like old files, garage door springs, or hay rake tines can be used, they often yield mixed results and must be spark-tested to ensure they have not been case-hardened. The best steel to use is W1 steel, which is easy to forge, quenches in water, and produces a large shower of sparks. The second choice is 1095 steel, containing 0.95% carbon, which requires oil quenching.

When forging the striker, our blacksmith carefully selects the appropriate amount of steel based on the desired size of the striker. The type and shape of the striker are meticulously planned. The steel is then heated in the forge, ensuring it does not overheat. Once heated, the steel is skillfully hammered into shape, forming a flat, striking surface and a decorative curl. After forming the striker, it is reheated until it becomes nonmagnetic and then quenched in oil to harden the steel. Finally, the striker is cleaned and the surface ground smooth, with great care taken to avoid overheating.

This traditional process ensures that each striker and piece of char cloth is as reliable as those from the 19th century, ready to serve for many years in the timeless craft of fire-making.