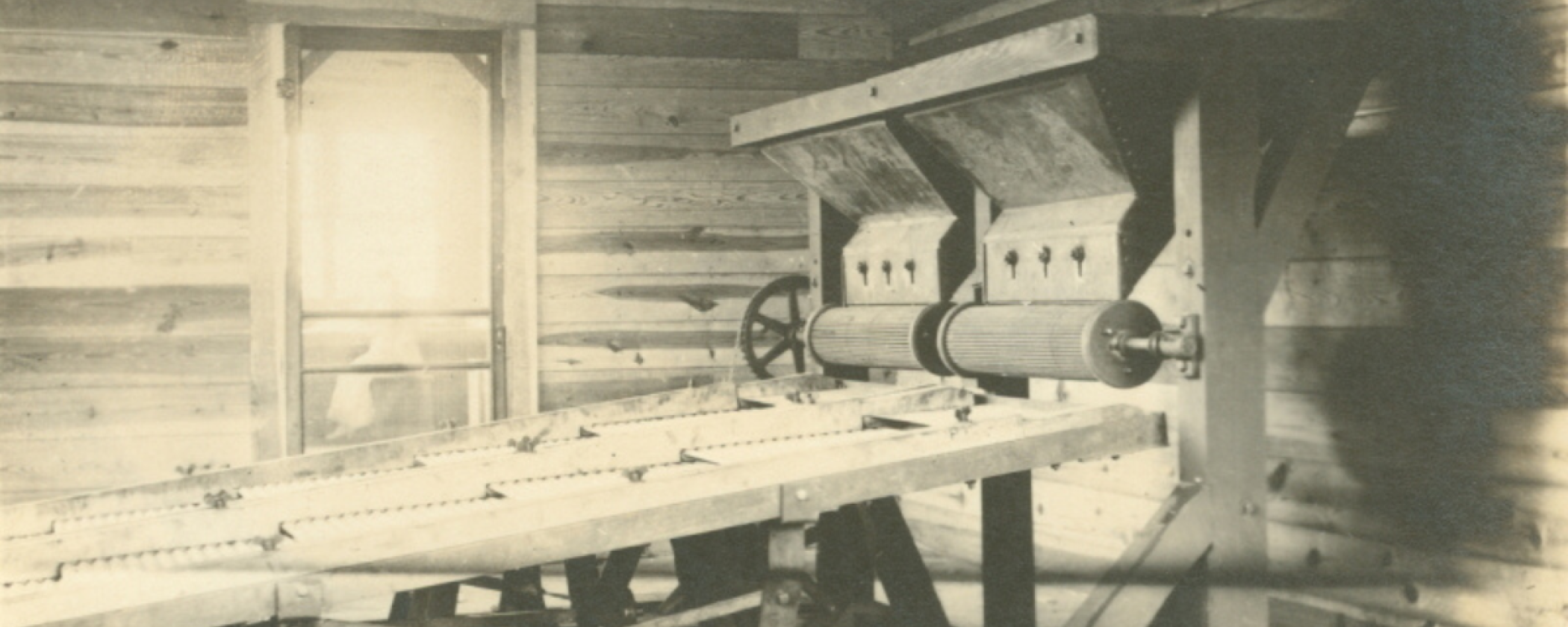

Artifact highlight: grease table

By: Sarah ReapGreetings from Crater of Diamonds State Park! Since the discovery of diamonds in Arkansas in 1906, prospectors have sought efficient new ways to search for this precious stone. Many of the early mine engineers who worked in the Arkansas mines had experience working in the African mines and would implement practices and equipment used in the African mines. One piece of equipment that was essential to the diamond processing plants in Arkansas was a grease table, or a “grease separator.”

A grease table is a multi-tiered diamond sorting device. This long, narrow table has several stair steps, or tiers, where a thick layer of grease is applied. Water is pumped through the top portion of the table and runs smoothly over the grease. After the grease has been applied and the water is running, fine diamond bearing material is poured onto the top of the table to begin separation. Most current grease table operations use a mixture of wax and petroleum jelly.

Grease tables were invented and used in the late 1890’s in the South African diamond mining town of Kimberley. This discovery greatly reduced the amount of labor for miners and limited the amount of material that had to be picked through by hand.

This device relies on the fact that diamonds are naturally hydrophobic, meaning they repel water. As water washes the diamond ore over the grease, other rocks and minerals wash off the table while the hydrophobic diamonds stay relatively dry and become lodged in the grease.

While miners sorted larger diamonds by hand, the grease table assisted with finding smaller diamonds. One report from the Kimberlite Diamond Mining and Washing Company refers to this machine as “unerring.” Noting that “even microscopic diamonds are ‘trapped’” and its “power of discrimination is little short of marvelous.” The Kimberlite Diamond Mining and Washing Company operated from 1912 until 1919 when a fire destroyed both processing plants and several other buildings on the property.

Despite great reports, grease tables require near-perfect conditions to be “unerring” and “marvelous.” The room temperature for a grease table should fall anywhere from 65 degrees Fahrenheit to 75 degrees Fahrenheit. Any colder and the grease becomes cold and hard, causing diamonds to slide right off the table. Any warmer and the grease becomes too sticky and messy.

This efficient piece of machinery was reproduced in Arkansas at the beginning of the diamond boom and was utilized in commercial diamond mines in Arkansas for many years. A modern-day replica of a grease table can now be seen in the lower level of the Diamond Discovery Center. This decorative fountain is a representation of what a grease separation device would have looked like in the original diamond processing plants where Crater of Diamonds State Park sits today. Check out this fascinating piece of Arkansas diamond mining history on your next diamond search!

Search area last plowed: August 27, 2023

Most recent significant rain: November 20, 2023

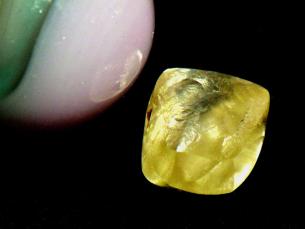

Recent diamond finds (100 points = 1 carat):

November 21 – Scot Darling, Duluth, MN, 17 pt. white; Scott Kreykes, Dierks, AR, .6 pt. white, 1 pt. white, 1 pt. white, 1 pt. brown, 6 pt. white

November 24 – David Murphy, Eupora, MS, 5 pt white, 2 pt. white

November 25 – Brad and Kathy Newton, Pearcy, AR, 17 pt. white